We at PRIVA REFRIGERATION, SUPPLY GASKET PLATE HEAT EXCHANGER — GPHE AND SPARES OF GPHE AS PER THE CUSTOMER REQUIREMENTS.

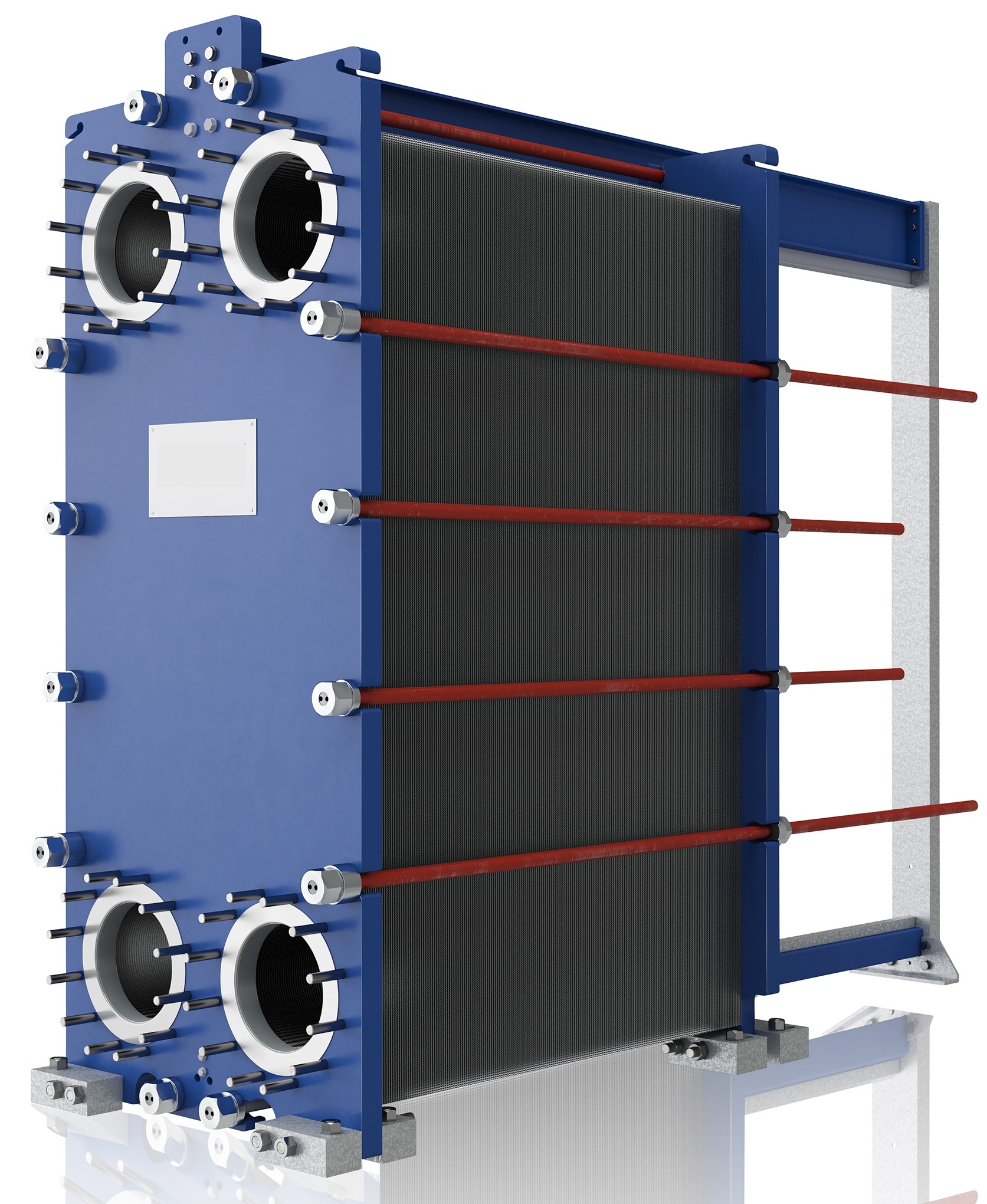

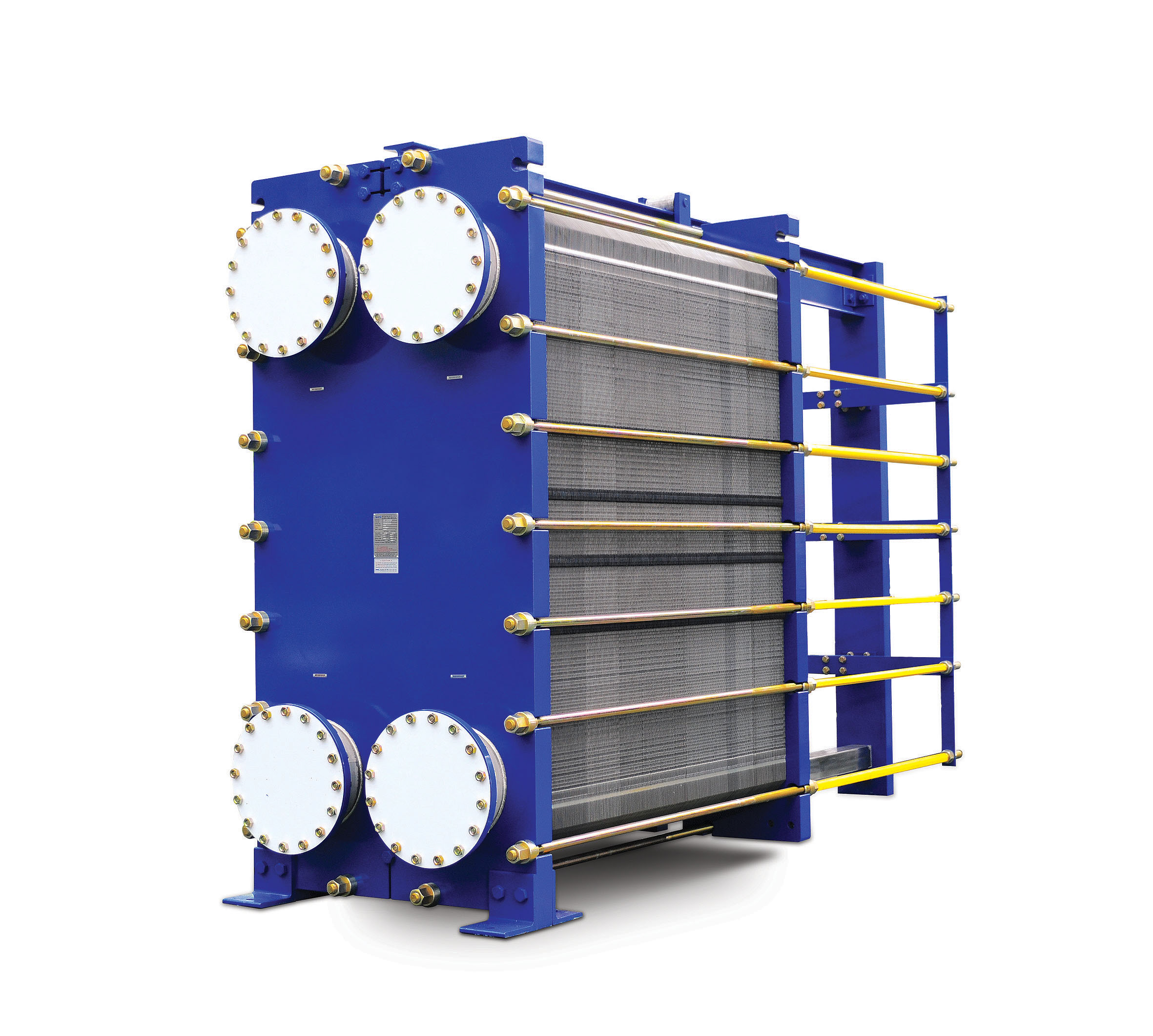

Our gasketed plate heat exchangers combine passion, scientific curiosity and technological expertise. The facts: High efficiency at low operating costs, versatile application possibilities with lower investment costs and maximum flexibility. Our efforts to continuously develop the gasketed plate heat exchanger-series further are aimed at meeting your thermodynamic and hydraulic performance needs and to ensure maximum economic efficiency. Our wide range of plate corrugations, connection sizes, materials, plate lengths and widths enable an ideal configuration according to your exact requirements. Our gasketed plate heat exchangers come with a maintenance-friendly assembly and sealing technology, ensuring low service and maintenance costs.

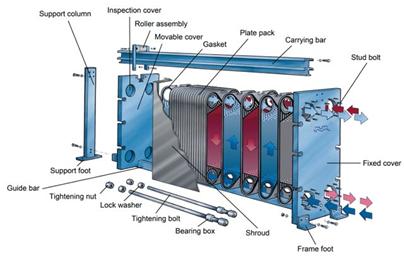

In a gasketed plate heat exchanger, the plates are fitted with elastomeric gaskets which seal the channels and direct the fluids into alternate channels. The plate pack is assembled between a frame plate and a pressure plate, and compressed by tightening bolts fitted between these plates. The channel plates and the pressure plate are suspended from an upper carrying bar and located by a lower guiding bar, both of which are fixed to the support column. The physical design of the gasketed plate heat exchanger allows easy cleaning and modification of capacity by the addition or removal of plates.

As the fluids pass through the heat exchanger, heat is transferred from the hot media to the cold media. Counter current flow enables maximum heat recovery possibilities and very close temperature approach can be achieved. Temperature cross is also possible, meaning that the hot outlet can reach a lower temperature than the cold outlet. This can only be achieved to a limited extent with tubular heat exchangers making plate-and-frame heat exchangers more thermally efficient.

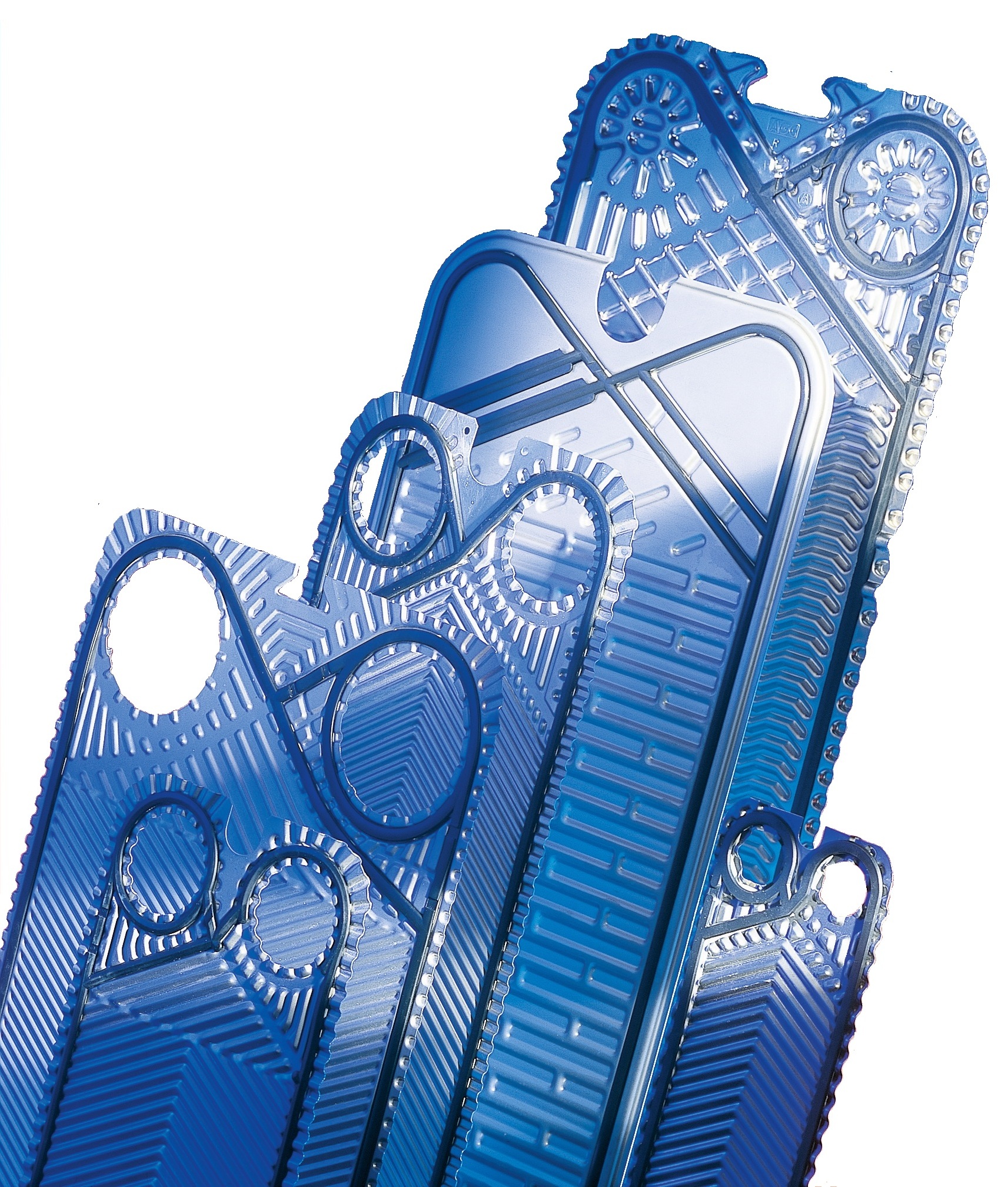

The fluids enter through the connections and portholes of the heat transfer plates. Specially designed sealing gaskets located between the plates direct the fluids so that the hot and cold fluids pass counter-currently in alternating channels. When the fluid enters between the plates, it passes over the distribution area. The distribution area is one of the most important features of a plate heat exchanger. Its main purpose is to ensure an even flow of fluid over the entire plate while maximizing heat transfer efficiency and minimizing maldistribution and fouling.

1. Save energy

Plate heat exchangers are up to five times more efficient than shell-and-tube designs with approach temperatures as close as 1°C. Heat recovery can be increased substantially by simply exchanging existing shell-and-tubes for compact heat exchangers. The result is more energy being put back to use, energy that would otherwise have gone to waste.

2. Save floor space

Shell-and-tube heat exchangers use significantly more floor space as plate heat exchangers.

The compact, versatile design of plate heat exchangers means that transportation, erection and installation costs are all drastically reduced compared to conventional shell-and-tube units.

3. Easier maintenance

High quality plate-and-frame heat exchangers can operate efficiency for over ten years without maintenance.

The heat transfer surfaces are easily accessible for inspection or mechanical cleaning, simply by removing the tightening bolts and rolling back the pressure plate. And special corrugated plate patterns ensure a high degree of turbulence over the whole plate, which not only reduces fouling but also makes cleaning very effective.

Frames can also be opened using standard tools, and there are no tube bundles to be pulled.

4. Lower capital costs

Plate heat exchangers weigh less than 1/16th the total weight of shell-and-tube exchangers and use 1/10th the floor space. That means immediate savings on shipping, handling, and installation costs. And, PHEs can be assembled and disassembled on-site.

5. Easy capacity adjustment

Plate heat exchangers make it easy to adjust capacity to meet changing needs, simply by adding or removing plates, while retaining the existing frame. This is a major advantage in relation to shell-and-tube units, where capacity is fixed at the level decided on at the time of installation.

High heat transfer efficiency.

Low fouling due to corrugations & inherent turbulence, hence reduce scaling problem.

Minimum 1 °C temperature approach with more than 90% heat recovery.

Simplified handling, quick and safe gasket replacement.

Optimized distribution of media.

Available in SS316, SS304, SMO254, Titanium, Hastelloy C-276 channel plates; NBR, EPDM, Viton gasket; MS epoxy painted/SS Clad frame based on the application requirement.

Food

Dairy

Chemical

HVAC

Marine

Pharmaceuticals

Beverages

Steel Industries

Hydraulic Oil Cooling

Quench Oil Cooling

Lubrication Oil Cooling

work in Heat Transfer solutions for various Industrial as well as Refrigeration applications

Copyright © 2020 privaref.com

Designed & Developed at New Era Design Studios