We at PRIVA REFRIGERATION, SUPPLY BRAZED PLATE HEAT EXCHANGER AS PER THE CUSTOMER REQUIREMENTS.

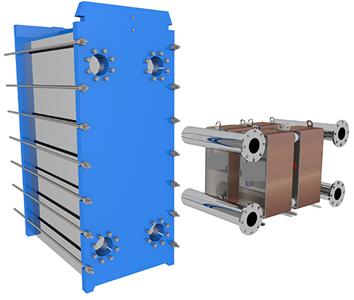

Brazed Plate Heat Exchangers, the brazing process eliminates gasketed joints which allows for higher design pressure and temperatures. The brazed plate heat exchanger (BHE) consists of thin corrugated stainless steel plates vacuum brazed together using copper as the brazing material.

The channel formed by two adjacent plates is the key to the plate heat exchanger’s high efficiency. The hot and cold fluids are distributed through alternate channels in a counter-current arrangement. This counter-current flow provides for maximum thermal efficiency. The flow pattern induces turbulence at very low Reynolds numbers, which also contributes to high heat transfer rates. Units are custom selected to effectively optimize the available pressure drop.

The fluid shear stresses in a plate exchanger are much higher than those of a tubular exchanger. This tends to keep the channels in a plate exchanger much cleaner. For clean services, the normal practice is to provide units designed for 100% of the surface area required. For fluids that foul, plate exchangers can be provided with 5-10% excess area.

Plate heat exchangers are well suited for applications that require close temperature approaches. (The approach temperature is defined as the hot fluid outlet temperature minus the cold fluid inlet temperature.) Units can achieve temperature approaches as close as 1°C.

Brazed plate heat exchangers (BHEs) are well-established components in refrigeration systems due to their compactness, durable designs, ease of installation and cost efficient operation.

Design :

Brazing the stainless steel plates together eliminates the need for sealing gaskets and thick frame plates. As well as holding the plates together at their contact points, the brazing material seals the package. BHEs are brazed at all contact points, ensuring optimal heat transfer efficiency and pressure resistance. The plates are designed to provide the longest possible lifetime. Since virtually all surfaces of the brazed plate heat exchanger actively contribute to heat transfer, the BHE is very compact in size, and it has a low weight and a low hold-up volume. We offers a wide range of standard heat exchanger models and sizes, tailor-made for a wide scope including refrigeration applications. Standard configurations are available from stock and customer-specific designs are available on request.

Flow principle:

The basic flow principle in a brazed plate heat exchanger for refrigeration applications is parallel or diagonal flow to achieve the most efficient heat transfer process. In a single pass design, all connections are located on one side of the heat exchanger, making installation very easy. Multipass design and different types of connections are available. Optionally, the location of connections can be chosen.

Flow principle in Evaporator design The channels formed between the corrugated plates and corners are arranged so that the two media flow through alternate channels, always in opposite directions (counter current flow).

The two phase refrigerant (vapour and liquid) enters the bottom left of the exchanger with a vapour quality depending on the operating condition of the plant. Evaporation of the liquid phase takes place inside the channels and some degrees of superheat are always requested, which is the reason why the process is called “dry expansion”. The water (brine) to be cooled flows counter current in the opposite channel.

Flow principle in Condenser design The main components are the same as for the evaporator. The refrigerant enters at top left of the exchanger as hot gas and starts to condense on the surface of the channels until fully condensed, and is then slightly subcooled. The process is called “free condensation”.

Our BPHEs are extremely compact compared with other technologies. The footprint can be as little as one tenth that of a shell & tube heat exchanger or half that of a gasket PHE.

Improved application efficiency.

Overall competitiveness.

Energy & environment saving.

Suitable for high pressure & temperature working.

Minimized footprint — highly compact design.

Available in SS316, SS304, SMO254 channel plates, Copper & Nickel brazing based on the application requirement.

Heating

Air Conditioning

Refregeration

Industrial

work in Heat Transfer solutions for various Industrial as well as Refrigeration applications

Copyright © 2020 privaref.com

Designed & Developed at New Era Design Studios